SOLD

Reference

:

E6436

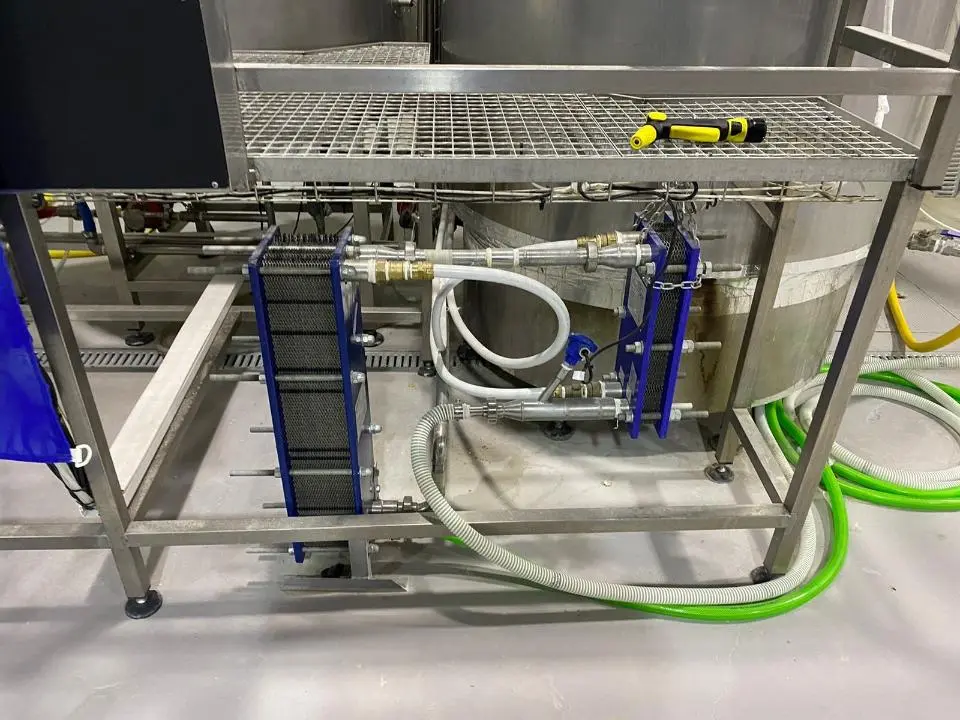

AUTOMATIC MICROBREWERY 1000 LITERS BACHT: With GAS heating system for the mashing and cooking process. Installed power 175/55 KW with double speed at 175/55 KW. Fully automated mash temperature ramp control with AUTOMATIC cleaning and fermentation process installed. (Heating 1 º C / 1.2 min at 100 º C) Suitable for different styles of beer (Ales, Lager, Pils, Weizen, Stout etc.). Yield: 1,500 Liters per cooking/batch per day. (Possibility of expansion) Made of AISI 316 quality stainless steel, polished quality interior and exterior finishes. ISOTHERMAL insulation with 80 mm rock wool. thick, mounted on the cylinder body and bottom. DN 32 INOX pipes, AISI 316 steel Lined insulated parts, finished in AISI-316 quality stainless steel. Welding is carried out in the TIG Argon procedure COMPOSED OF: *Macerator + Filter: 1,000 L useful for Maceration and Filtering with included and automated cleaning device, insulated and stainless steel finish. Tank exchanger: 1,000 L useful, insulated and stainless steel finish. for temperature exchange in the mashing steps and different production processes. Kettle + Whirlpool + Filter of 1400 L with combustion chamber: Insulated and stainless steel finish, for boiling, filtering and aspiration using a recirculation pump, the Whirlpool is integrated into the Boiling Tank + Hops Filter. Includes tangential mouth inlet and outlet, discharge nozzle, slightly inclined bottom to avoid accumulation and improve cleaning. LAMBORGHINI burner with regulation and automatic start and safety sweep system. INOX plate heat exchanger. Food transfer pumps for recirculation, etc. performance 4,000 Liters / hour and 2,000 Liters / hour controlled by an electronic speed controller connected to the automatic system Installed power pumps 1 KW./ unit. STAINLESS STEEL pipes. DN 32 interconnection, AISI 316 steel AISI 316 stainless steel manifolds GENEBRE pneumatic valves with assisted and automated inclined seat. Access ladder to the upper part of the cooking room made of stainless steel and tramex with work platform MONKEY AUTOMATIC BREW CONTROL PANEL SHENEIDER Fermentation CONTROL SOFTWARE included for 4 expandable fermenters. Width 2,000 x Length 4,500 x Height 2,000 APPROX CYLINDEROCONICAL ISOTHERMAL ATMOSPHERIC FERMENTER WITH CONICAL BOTTOM OF 60º WITH LEGS AND COOLING JACKET FOR FERMENTATION AND MATURATION OF BEER Made entirely of stainless steel AISI Quality – 304 with quality interior and exterior finishes (BA POLISHED). Welding is carried out in an automatic TIG Argon procedure with a protected atmosphere. The interior surfaces of the tanks will be delivered completely smooth, being able to guarantee maximum conservation of the product and facilitating its subsequent cleaning. CHARACTERISTICS The fermenters are made up of: ON THE ROOF “DOME”: 1 Round isobaric door diameter 400 mm 1 Domed “Cloper” type dome. 1 Pressure safety valve set at 2.8 Bar. IN CYLINDER BODY: 1 Pressure control manometer. 1 Micro - CO2 connection. 1 Cooling jacket. (In cylinder body). 1 Level with protection strip. 1 Sheath for temperature probe (The probe is not included). 1 Expintex ISOTHERMAL insulation, 70 mm thick, mounted on the cylinder body and on the lower conical bottom. Exterior lined insulated parts, finished in AISI-304 quality stainless steel. 1 60° conical bottom. 1 Butterfly valve DN 32 for partial outlet, sanitary thread connection 1 Ball valve DN 32 for total outlet, sanitary thread connection NW 32. 4 Legs diameter 104 mm. with 18 mm diameter bracing. CHARACTERISTICS CAPACITY 10 HL LITERS 1,000 DIAMETER 1,500 mm HEIGHT 3,000 mm. COMPACT REFRIGERATION EQUIPMENT C211 STAINLESS STEEL. Built for cooling the must and controlling the alcoholic fermentation of the fermenters. Glycol water cooler with circulation pump, accumulation tank and hydraulic accessories, with additional thermostat for temperature control. FEATURES: The C211 refrigerator automatically controls up to 8 applications thanks to the control panel and the installed components. The machine incorporates all the accessories of the hydraulic circuit, such as a circulation pump, accumulation tank with corresponding safety devices (expansion tank, safety valves, level detector...). SECOND-HAND STAINLESS STEEL MALT MILL For malt grinding, a two-cylinder machine with a performance of 200 kg/h (Adjustable) is used. It has a hopper at its entrance with a safety and protection grid and a strong magnet to separate all metallic impurities. Installed power 1.5 KW.

Related products